The new revolutionary compressor from Atlas Copco

With its innovative vertical design, Atlas Copco’s GA 7-37 VSD + brings a game-changing revolution in the compressor industry. It offers Variable Speed Drive as standard, a compact motor and footprint thanks to its in-house design and iPM (Permanent Magnet) technology. The GA 7-37 VSD + reduces energy consumption by on average 50%, with uptimes assured even in the harshest operational conditions. The GA 7-37 VSD + is the air compressor of the future, designed in-house by Atlas Copco. It will set a new standard for years to come, positioning Atlas Copco as a leader in the compressed air industry.

EFFICIENT

• On average 20% lower Specific Energy Requirement (SER) than the current GA VSD models. Eco-efficient VSD + reduces energy consumption by on average 50% compared to the current idling models.

• On top of energy savings, Free Air Delivery (FAD) increase of up to 12% over the range.

• Efficient fan motor (ERP 2015) reduces electricity consumption and noise levels.

• Highest motor efficiency (iPM), up to 96.8%, outperforming IE3 efficiency levels.

RELIABLE

• Low maintenance: fewer components, increased uptime.

• Worry-free: the GA 7-37 VSD + has been extensively field-tested over three years.

• Based on unique combination of proven technologies and existing components, optimally brought together by Atlas Copco’s unique experience and know-how.

SMART

• Elegant and revolutionary design.

• Frequency-controlled operation as standard (VSD + ), integrated dryer available.

• Fewer components & few options: impressive list of standard features.

• Ecological design, efficient material usage.

Small compressor, big ideas

INNOVATIVE VERTICAL DESIGN

Atlas Copco has turned the compressed air industry on its head by redesigning the conventional layout of a typical air compressor. Instead of the normal space-taking horizontal design, the new GA 7-37 VSD + has an upright, vertical, low footprint layout. This saves valuable floor and work space, eases maintenance access, accelerates manufacturing time, and reduces the total cost of ownership for all customers.

COMPACT

• Extremely small footprint.

• Clever design allows the GA 7-37 VSD + to be placed against a wall.

• Robust: motor is oil-cooled; element rotor and motor have the same axis.

• Drive train: direct connection between element and motor.

• Very low noise level, with separate compartments for drive train and cooling.

Inside the innovative GA 7-37 VSD +

The GA 7-37 VSD + is packed with innovative features that increase its efficiency, cut its energy consumption, lower its noise levels, and reduce its operating costs. In addition, it meets or even exceeds all currently applicable standards.

Atlas Copco’s GA Variable Speed Drive + (VSD + ) technology closely follows the air demand by automatically adjusting the motor speed. Combined with the innovative design of the iPM (Permanent Magnet) motor, this results in average energy savings of 50% and an average cut of 37% in the lifecycle cost of a compressor. VSD + works with permanent, in-house designed magnet motors.

Why Atlas copco variable Speed drive + Technology?

• On average 50% energy savings with an extensive flow range (20-100%).

• Integrated Elektronikon ® Graphic controller controls the motor speed and high efficiency frequency inverter.

• No wasted idling times or blow-off losses during operation.

• Compressor can start/stop under full system pressure without the need to unload with special VSD + motor.

• Eliminates peak current penalty during start-up.

• Minimizes system leakage due to a lower system pressure.

• EMC Compliance to directives (2004/108/EG).

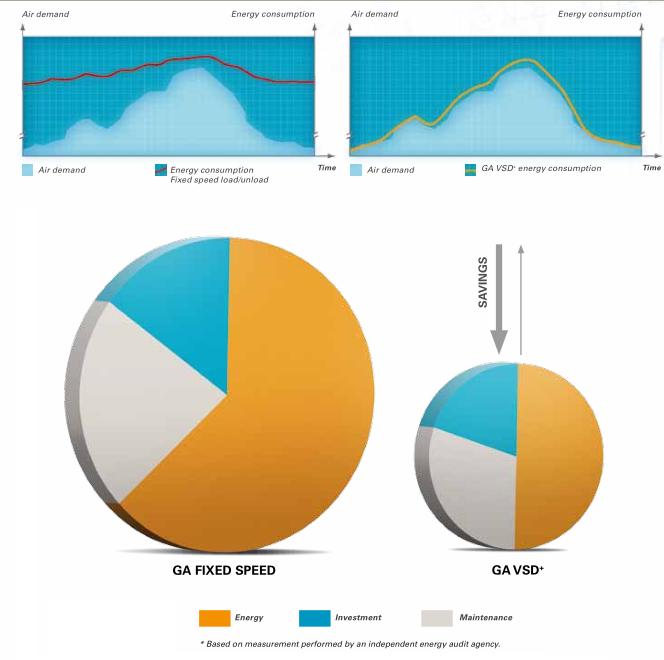

VSD + for 50% average energy savings*

In almost every production environment, air demand fluctuates depending on different factors such as the time of the day, week or even month. Extensive measurements and studies of compressed air demand profiles show that many compressors have substantial variations in air demand.

A step ahead in monitoring and controls

The next-generation Elektronikon ® operating system offers a wide variety of control and monitoring features that allow you to increase your compressor’s efficiency and reliability. To maximize energy efficiency, the Elektronikon ® controls the main drive motor and regulates system pressure within a predefined and narrow pressure band.

The next-generation Elektronikon ® operating system offers a wide variety of control and monitoring features that allow you to increase your compressor’s efficiency and reliability. To maximize energy efficiency, the Elektronikon ® controls the main drive motor and regulates system pressure within a predefined and narrow pressure band.

Dual pressure set point

Most production processes create fluctuating demands which, in turn, can create energy waste in low use periods. Using the Elektronikon ® , you can manually or automatically create two different system pressure bands to optimize energy use and reduce costs.

Week timer

An on-board clock enables timers to be set up to support any working scheme – per day, per week or completely customizable to your specific situation and needs.

Integrated Saver cycles

Fan Saver Cycle reduces the energy consumption by switching off the fan in light load applications. Using an ambient sensor to monitor the required dew point suppression, the Elektronikon ® starts and stops the dryer, minimizing energy use.

Excellence in integrated air quality

Untreated compressed air contains moisture and aerosols which increase the risk of corrosion and compressed air system leaks. This can result in a damaged air system and contaminated end product. Maintenance costs can far exceed air treatment costs. Our compressors provide the clean, dry air that improves your system’s reliability, avoids costly downtime and production delays, and safeguards the quality of your products.

SAVE MONEY AND THE ENVIRONMENT

Avoid risk of corrosion and system leaks, and ensure the effective safe disposal of untreated condensate – all within ISO 14001 standards.

ON AVERAGE 50% ENERGY SAVINGS WITH NEWLY DESIGNED INTEGRATED DRYERS

1. Pressure dew point of 3°C (100% relative humidity at 20°C).

2. Unique Saver Cycle Control, with ambient temperature sensor and based on dryer load and relative humidity of compressed air, saves energy at partial load.

3. Heat exchanger cross-flow technology with low pressure drop.

4. Zero waste of compressed air thanks to no-loss condensate drain.

5. Reduced operating costs.

6. Environmentally-friendly characteristics; zero ozone depletion.

7. Global warming potential has been reduced significantly by an average of 50% by reducing the amount of refrigerant in the new dryer.

Driven by innovation

With more than 140 years of innovation and experience, Atlas Copco will deliver the products and services to help maximize your company’s efficiency and productivity. As an industry leader, we are dedicated to offering high air quality at the lowest possible cost of ownership. Through continuous innovation, we strive to safeguard your bottom line and bring you peace of mind.

Building on interaction

As part of our long-term relationship with our customers, we have accumulated extensive knowledge of a wide diversity of processes, needs and objectives. This gives us the flexibility to adapt and efficiently produce customized compressed air solutions that meet and exceed your expectations.

A committed business partner

With a presence in over 170 countries, we will deliver high-quality customer service anywhere, anytime. Our highly skilled technicians are available 24/7 and are supported by an efficient logistics organization, ensuring fast delivery of genuine spare parts when you need them. We are committed to providing the best possible know-how and technology to help your company produce, grow, and succeed. With Atlas Copco you can rest assured that your superior productivity is our first concern!